Industrial Engineering and automation as tools for successful business

Por Mariela Mendez

Mexican industry especially SMEs have been hit considerably from 2008 due to the impact of the global economic crisis. This is extremely serious because they provide a significant percentage of national GDP, and will face new challenges in order to survive and succeed. That's why they should make use of new strategies as the use of the characteristics of industrial engineering tools to help analyze, manage, create, redesign, enhance, implement and monitor business processes.

Two important elements to consider: competitiveness and productivity.

There are two important factors that companies must take into account in order to achieve success, competitiveness and productivity. These indicators show employers what position the company is in the market. Competitiveness is the ability of companies to be faced with other, from another point of view "competitiveness has become a necessity for the survival of businesses. Companies compete in the increasingly broader markets in which they participate. "(Sastre, and Miguel Aguilar, Eva, 2000). Meanwhile productivity is generated by the company, the EPA (European Productivity Agency) says that productivity It is the degree of effective use of each element of production.

So for entrepreneurs to maintain their prosperous and successful company must be competitive and productive. To accomplish this must perform deep inspection processes found within these. This time we will focus on production processes, as they are closely related to productivity and in turn if these are improved competitive advantage may be seeing reflected in the final products.

How are Mexican SMEs?

According to information provided to us by legislators in the Senate Gazette it is known that because of the global economic crisis that affected the country's economy, the GDP decreased by 8% in the first quarter of this year. The industrial sector is important to mention that 96% of its establishments are SMEs, which account for 70% of GDP.

According to information provided to us by legislators in the Senate Gazette it is known that because of the global economic crisis that affected the country's economy, the GDP decreased by 8% in the first quarter of this year. The industrial sector is important to mention that 96% of its establishments are SMEs, which account for 70% of GDP.

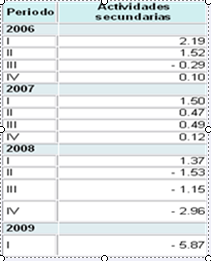

In this article, as mentioned previously, we will focus on the production processes of companies. The situation of those secondary activities that are responsible for the transformation of the raw material is analyzed. A table appears with the INEGI data where GDP growth of secondary activities is shown from 2006 to 2009.

It is noted that from the second quarter of 2008 the contribution to GDP of secondary activities decreased substantially. Accordingly employers will have to improve or restructure their strategies to achieve the desired objectives.

Why Mexican SMEs fail?

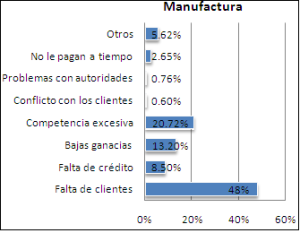

According to research conducted by the INEGI it was found that the main causes of failure of SMEs is eight where mainly highlight the low demand of the market with 48% and excessive competition with 21% of companies surveyed.

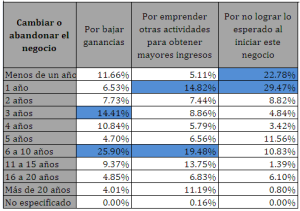

Moreover according to the expectations of the owner main reasons why an SME ceases to exist or changes of rotation are: lower profit, undertake other businesses and for failing expected to start up a business, among others as hired as an employee for personal reasons or other reasons.

As for the life cycle of an SME it varies depending on the reasons why the business is abandoned. For example we can see that because of the low profit there is an average desist from 6-10 years, while the cause of starting a new business to earn more income have an average life of 1 year or at best the cases of 6-10 years. However we can see that by not achieve the expected objectives entrepreneurs decide to leave the business in an average of one year or less.

Executive woman tells us that the main factors influencing the failure of SMEs are administrative errors, financial and fiscal problems, issues and conflicts of production inputs. Another factor to consider is the lack of planning in business since many SMEs have strategies based on the owners own hunches, which in the absence of good preparation and structure tend to take the business to fail.

Many Mexican products do not meet the quality standards required to be competitive and neither has the necessary philosophy to continually improve production processes that are critical to business productivity. In the same way entrepreneurs do not have enough vision and budget to invest in technology and innovation for products and processes.

Currently no longer enough that a company has comparative advantages, ie they equalize advantages that your competition but must have competitive advantages that make them unique and better than their competitors.

The Industrial Engineering to the rescue!

We are having analyzed the above information we can say that Mexican businesses face a new paradigm where flexibility, productivity, competitiveness and adaptation to change are goals to be achieved. For this it is elemental to take into account the tools provided Industrial Engineering, given that thanks to these many problems that arise in the industry may be eliminated or reduced significantly.

The goal of industrial engineering is to identify, design, select, enhance the efficiency and optimize processes in any industry to make better use of resources. Even it takes care to ensure the productivity and competitiveness of enterprises while the quality of the products or services it offers. It also helps to develop and plan strategies that integrate different areas where decisions must be made of processes, administrative, quality, plant capacity and operational. Industrial Engineering participates integrally with a systemic approach that evaluates options for continuous improvement in all company processes.

SMEs must be prepared for change, ie be flexible and able to face any situation that arises as the current crisis. So companies will have to invest in technology and analysis of improvement in their production processes to meet changing demands and avoid making excessive competition to differentiate their products to other companies.

Part of industrial engineering focuses on the analysis, improvement, innovation and development of production processes, as they are the main processes that add value to the products of companies from secondary activities, through tools and methodologies of lean manufacturing that reduce costs, waste, eliminate downtime and increase productivity.

The areas covered by the Industrial Engineering to Increase the productivity of a company are:

• Industrial Security

• Manufacture process

• Quality and quality control

• Management of materials, machinery and tools

• Design of facilities

• Ergonomics

However, the Industrial Engineering can not design an efficient system of production without a major factor as automation technology, which increases the speed of response to customers, the accuracy of the process and hence the productivity of the company. Therefore should be able to know, evaluate and integrate different types of technologies to previously designed, developed and tested processes because currently a company can not become competitive if it does not have technological innovations.

But why industrial automation?

Stories of success

Following two successful cases where the benefits of the intervention of the tools offered by the Industrial Engineering and Automation application where significant results were shown are presented.

The first case is that of Sellopack SA is a Colombian SME dedicated to the packaging industry, some products are comparable bags open and close easily.

The main problems were found in the company were in the process of production as a result of many of the activities were manual, time-consuming and generated many errors. Also the machinery used in this type processes high temperatures generated in the work area and used a cooling system which consumed a lot of energy increasing business costs.

Sellopack had to resort to proprietary tools of industrial engineering and automation. In the first instance an analysis of the production process where it was found that in the extrusion line of polyethylene film should be automated in activities requiring greater accuracy while others should be performed by workers manually performed. As for the cooling system of the company it could be replaced by another to increase the cooling capacity. These changes achieved a productivity increase of 21% and a reduction of energy losses in the cooling system of 40%. The changes were made for the good integration between Engineering and Industrial Automation.

Another success story is that of a restaurant located in Tokyo, Japan called "100 Yen Sushi House". This restaurant could pass as any other, but what sets it apart from others is the system being implemented.

One of the main philosophies studying industrial engineering is the "Just in Time" system which was created by Toyota, an automotive company whose objective was to produce just what was required. Likewise the owner run Sushi House thought this philosophy to his restaurant because he realized that shared similar to a car company objectives.

The first thing he did was to analyze the demand of its dishes, so only the expected amount was cooked in the expected time avoiding the constant use of refrigerators, also had to make an agreement with its suppliers so that they were going several times a day and they were surtiendo, significantly reducing electricity costs. Besides all the dishes cost 100 yen, easing the work of cashiers and reducing the waiting time in the collection.

In these case studies we saw the importance and the great benefits that the Industrial Engineering and Automation bring to SMEs, if they are properly applied etas successful companies will be virtually assured. It is noteworthy that automation can not only be implemented in the production process but in any existing business process in an organization.

Finally it is important that SMEs in this time of crisis to invest in technology and process improvement, considering that in this way can be competitive and productive. There are companies responsible for the improvement and process automation for small and medium companies that offer affordable because they know the limitations and needs of these.